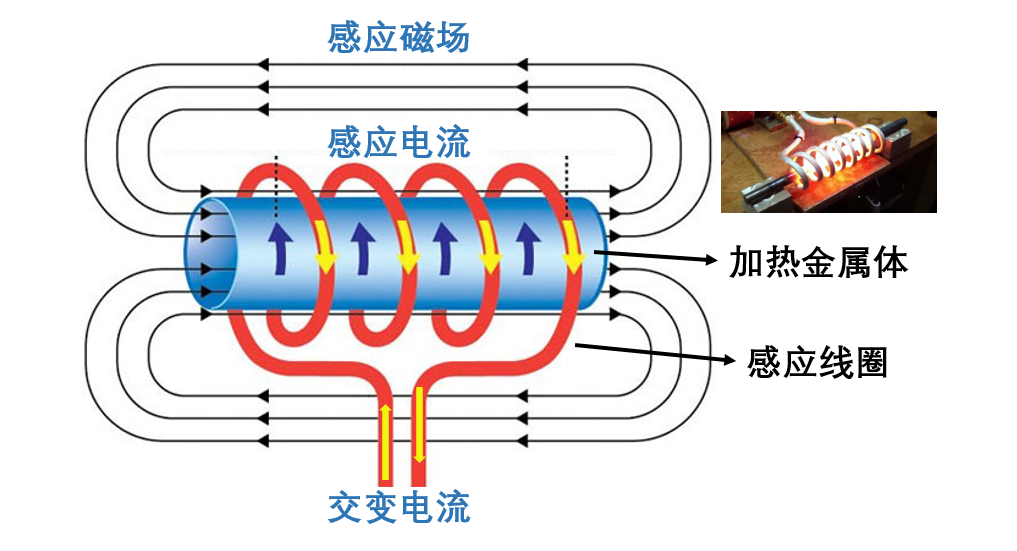

The basic principle of electromagnetic heating smoking tools(heat-not-burn) is that high-speed high-frequency high-voltage current (ie, alternating current) passes through the induction coil to generate a changing alternating magnetic field, and eddy current is generated on the metal induction body by cutting the alternating magnetic field lines. High-speed motion generates thermal energy, and uses thermal energy to heat objects.

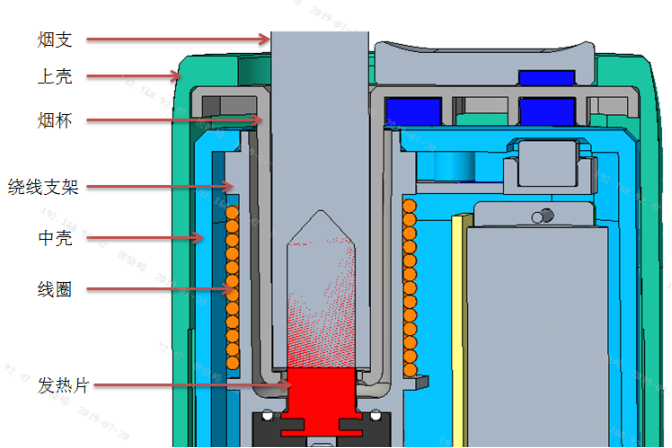

Therefore, in the structural design of smoking sets, the core components mainly include heating sheets, coils, heat insulation components (cigarette cups), etc., which bring about the following problems:

- What material is suitable for the heating element?

- What material is good for thermal insulation components?

- How many turns of the coil are optimal?

- How big is the diameter of the cigarette cup, which heats up the fastest?

According to the academic exchange report of tobacco technology, Dr. Li Bin’s team from the Key Laboratory of Tobacco Industry Technology recently cooperated with the automation team of China Tobacco Yunnan and Kunming University of Science and Technology, and selected COMSOL Multiphysics simulation software to carry out no-load heat transfer of micro-heaters of different structural sizes and materials. In the process, multi-physics simulation analysis of electromagnetic field and temperature field of electromagnetic heating cigarettes.

The simulation analysis results show that:

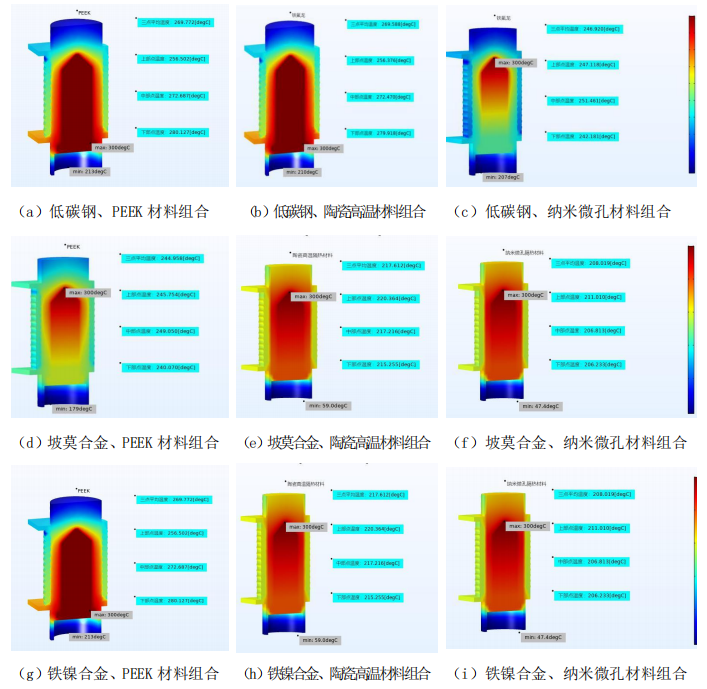

- Heating plate : the material is low carbon steel, the average temperature is high, the average temperature of iron-nickel alloy and permalloy is slightly lower, but the temperature difference between each part is small;

- Heat insulation parts : When PEEK material is used, the external temperature of the cup body is lower, and the heat insulation effect is better;

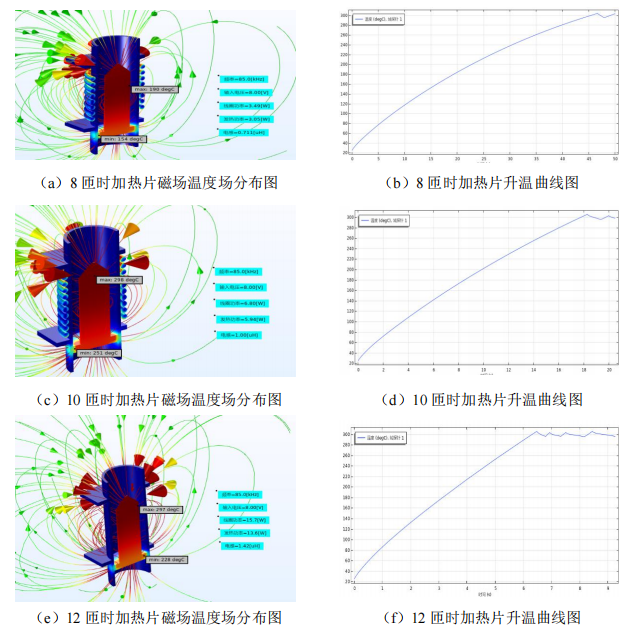

- Number of coil turns : the more the number, the shorter the heating time and the less energy required, but 12 turns are basically close to the upper limit in a limited space, and 12 turns are the most suitable number of turns;

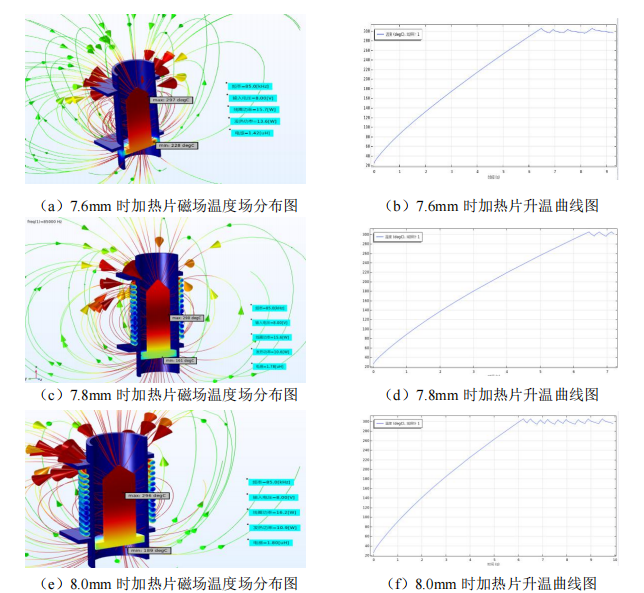

- Diameter of cigarette cup : The heating time of different cigarette cup diameters is close, and it can meet the requirements, but as the diameter of the cigarette cup becomes larger, the heating efficiency decreases.

Fig. Magnetic field temperature field and temperature rise curve of heating plate with three different cigarette cup diameters